need for

development

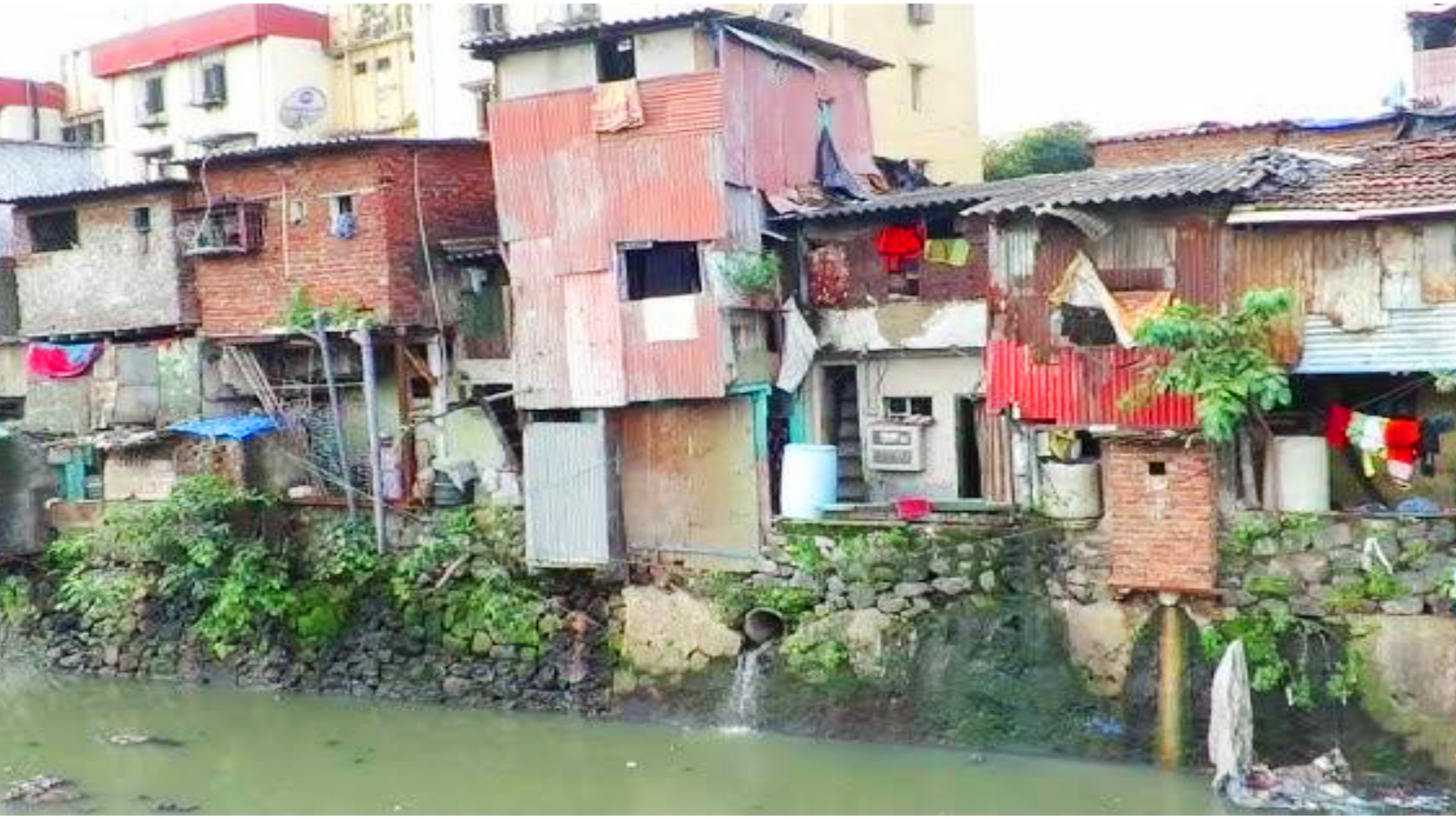

dharavi: industrial innovation amidst adversities

Leather The leather industry has always been an important pillar in the Dharavi economy, in 1887 the migrants from Tamil Nadu had the first tanker. Tanning was banned in 1996 due to pollution concerns, which, which relocated to the industry Deonar, is still alive. The community in Uttar Pradesh, Tamil Nadu and Maharashtra mainly dominates this business and brings more leather in Chennai and Kanpur. Various leather items are made in Dharavi-Pers, bags, belts, jackets, shoes, hats, etc.-which are sold at 90 feet road, all over Mumbai, on e-commerce platforms as well as international markets.

The decline of Mumbai's textile industry Dharavi's textile industry emerged due to the decline in the textile industry in Mumbai in the 1950-60s, which is currently spread in different parts of the production-Hosiery tracks and T-shirts are formed at Kalabakhar, while Kharta and Paganas are made at Khambedev. Jeans and other fabrics, such as shirts, are also made locally or in the nearest parts. Migrant workers from Uttar Pradesh, Bihar, Tamil Nadu, Karnataka and Kerala are the main pillars of this industry. The raws like cloth are brought from Surat, while threads and zips are available in Dharavi. These garments are sold by local road retailers, wholesale traders and exported to international markets.

Migrant potters Saurashtra, migrants from Gujarat Ceramic In Dharavi, Kumbharwada (Kumbhar Vasti) was established at a junction of 90 feet and 60 feet on a junction of about 12.5 acres. Each house in this area also plays the role of a workplace, which usually has a clay furnace (personal or shared) and a shopkeeper on the road. The soil used is brought from Gujarat, and compared to other Dharavi industries, the soil utensils are mainly made for local customers. The maximum number of pot shops in the potter's pots is 90 feet on the road, and in the community, women also contribute to decorative coating or color on products.

dharavi: a tapestry of traditional industries

and migrant enterprise

Dharavi's plastic recycling The industry plays an important role in the management of Mumbai's waste, recycling about 80% of the city. Ragpickers collect garbage throughout Mumbai, which are then classified into the recycling unit of Dharavi. Plastic is strictly separated, crushed in chips, and sold throughout the city to reuse the product. In addition, Dharavi has the industry of aluminum bricks, where aluminum bricks are produced by melting metal waste.

Dharavi's food production The department is an important part of the local economy, where many small businesses and home units produce traditional Indian snacks and baked foods. Papad, salt biscuits, butter biscuits, fresh buns, furs, Idli are often created in a limited space, often manufactured by family running businesses. These products are distributed throughout the city with local markets, reaching street traps, restaurants and catering services.

In Dharavi, embroidery This is an important craft type, young children in Bengal and Bihar are specialists in hand embroidery and Jardozhi, creating subtle patterns on clothing and decorative fabrics in a workshop or home environment. On the contrary, the machinery is mainly handled by the Bengali community, where it is manufactured faster and widely using semi-automatic or computerized machines. This division is a reflection of a combination of traditional craftsmanship and modern technology in Dharavi, in which the basis of regional skills and immigrant workers is important.